|

|

|

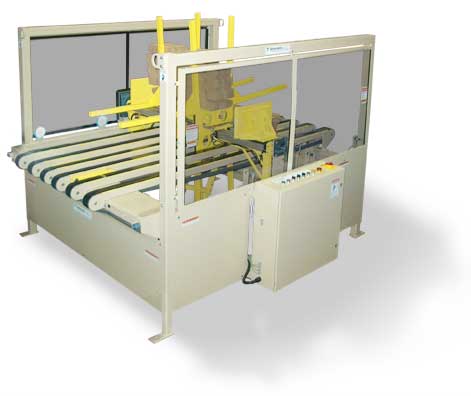

Die cut bundles are notoriously difficult to straighten. Tipping them on edge is the most effective way to straighten them. That’s exactly what our innovative Die Cut Bundle Squaring Station (DCBSS) does. Each bundle is tipped 90º and held vertical as it is gathered and tamped from the bottom and sides. Bundles exit the machine inverted and amazingly straight. This machine is ideal for all kinds and sizes of die cut material but is particularly effective for large, heavy, hard to straighten bundles. Here are some details:

Two models:

- DCBSS 30-36 for bundles:

10” - 30” (254 - 762 mm) through

18” - 36” (457 - 914 mm) across

3” - 12” (76 – 305 mm) tall

Straightens up to 15 bundles per minute

- DCBSS 36-48 for bundles:

10” - 36” (254 – 914 mm) through

24” - 48” (609 – 1219 mm) across

3” - 12” (76 – 305 mm) tall

Straightens up to 12 bundles per minute

Features:

- Adjusts to your conveyor’s height

- Sets up easily in seconds for bundle size

- Finger-safe guides keep belts centered and prevent sheets from getting under the belts

- Brake outputs are included for upstream conveyor to control bundle flow

- CE compliant guarding, 24 VDC controls and 0-energy disconnects make this a very safe machine. UL certification is available upon request.

- Includes a comprehensive Owner’s Manual with sections on safety, installation, start up, operation and maintenance.

- The Die Cut Bundle Squaring Station has a durable powder coated finish

|

|

|

|

Click for Details

|

|

Vertical Straightening

|

|

Transfer Bundles on Center

|

|

|

|